+86-13914052243

The CNC EDM technology connects the workpiece and the electrode without actual contact can realize the processing of difficult-to-cut materials and complex shapes, can realize multi-axis simultaneous processing and is widely used in the industrial field. Most of the equipment in the aerospace field requires professional customization, and the processing is difficult.

The use of CNC EDM technology can optimize the processing of key components of the aerospace engine. Among them, the processing technology of the integral turbine disc with a blade is the most prominent and reliable. In order to improve the actual performance of the launch rocket, high-reliability engines are the top priority. The integral turbine disc is the core of the engine. It needs to withstand high temperature and high-speed operation and can withstand thermal shocks and alternating loads. The turbine disc design affects engine performance. The use of CNC EDM machine technology can realize multi-axis simultaneous operation and Flexibly solve the problem of mutual interference between electrodes and blades in turbine disk machining, the processing effect is ideal.

The Application of CNC EDM Technology in Aerospace in the International Market

The manufacture of integral turbine disks for aerospace engines is a key part of the engine. The turbine disks have complex structures and extremely high machining accuracy requirements, and the blade surfaces are curved and complex in shape. They face high temperature and high-pressure threats during operation. Highly resistant materials such as titanium must be used. Alloys, high-temperature alloys, titanium-based and titanium-aluminum compounds are the basic materials. See how an aluminium wire cutting machine works here. The use of new materials used in EDM aerospace has greatly reduced the machinability of the turbine disk, and the overall mechanical manufacturing burden of the turbine disk is heavy. The use of traditional mechanical manufacturing cannot meet processing needs.

In aerospace engines, the use of advanced integrated turbine disks with a crown greatly improves engine performance. However, with the improvement of quality superiority, corresponding parts processing also faces certain difficulties. Integral turbine discs with blade crowns have certain unique characteristics:

(1) It is mostly made of high-temperature alloys and titanium alloys, and the material processing is pretty difficult.

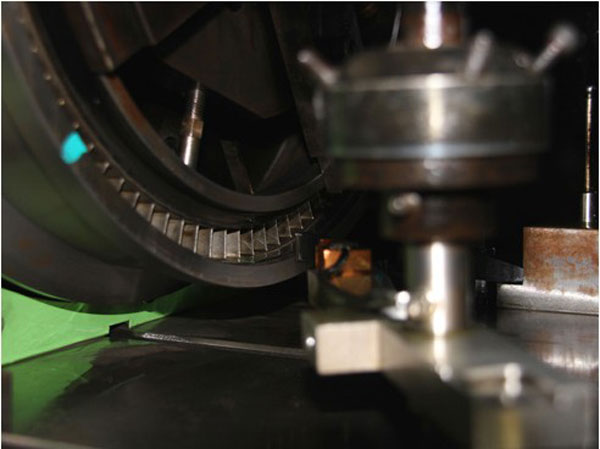

(2) The structure is complex, it is a semi-closed structure with a leaf crown and adopts a two-pole roulette structure design with a leaf crown, and the processing involves complicated irregular cutting.

(3) The operation of aerospace engines is related to the safety of the personnel in the cabin. The design of the integral turbine disk with a crown of the engine has strict requirements on the size and precision, and strict requirements on the shape and position tolerance.

The integral turbine disc is centered on the design structure with the blade crown, and its proportion in the aerospace field is gradually increasing, and it is an important component of the future aircraft engine. At present, multi-axis linkage CNC EDM is an important technology for the rational processing of integral turbine discs. It is necessary to pay attention to in-depth research on 4-5 axis linkage CNC EDM equipment technology, master the core technology and put it into market use.

For users, the application database is mainly to give play to the resource advantages of the equipment process database, improve the processing effect, and obtain satisfactory processing works. With the process database, the corresponding equipment manufacturer needs to continuously conduct process tests to verify the reliability of the processing with the test result data. In addition, it is necessary to improve the processing accuracy of the equipment, control the pros and cons of the pulse power supply, and maximize the value of the process database, so that the process database provided by the equipment is accurate, reliable, and instructive, and can be used flexibly by users.

In addition, titanium alloy materials are quite different in the database of CNC EDM machining technology. It is necessary to actively explore other a CNC spark erosion advantages and characteristics in addition to the advantages of titanium alloy material processing.

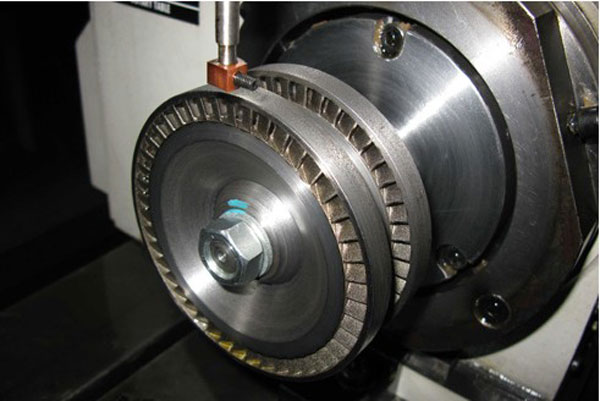

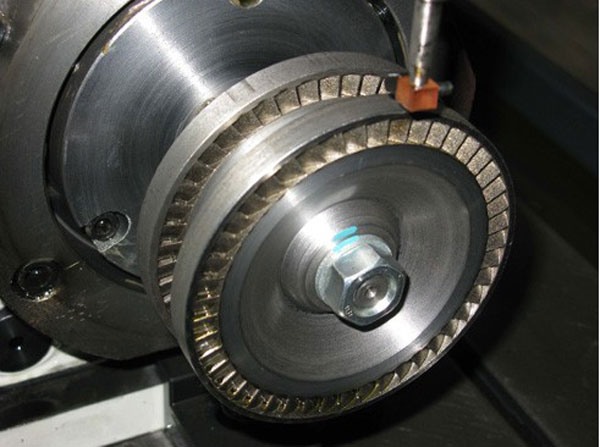

The CNC rotary table corresponding to CNC EDM needs to meet multiple conditions. First, it has been in an oil-immersed environment for a long time and needs to work normally in this environment; secondly, the CNC rotary table needs to have various angle indexing functions, which can bear servo motion axes; secondly, its angular positioning accuracy must be below 14.4". At present, the accuracy of domestically made CNC rotary tables suitable for CNC EDM is not high. The reasonable application of CNC EDM technology in the aerospace field requires attention to improve the accuracy of CNC turntables.

To sum up, with the continuous development of the national economy today, the national defense technology level is constantly improving, and CNC EDM technology plays a key technical role in the aerospace industry, and the processing results in important technologies are relatively satisfactory. The demand for the defense technology industry continues to increase, and the application prospects of CNC EDM technology are broad. CNC EDM technology needs to focus on research and development in the direction of multi-axis linkage precision CNC EDM machine and high-precision CNC turntables, breaking through the mass production of core components Bottleneck, establish a high-end material technology database, and promote the scientific application of CNC EDM technology in defense aerospace science and technology.

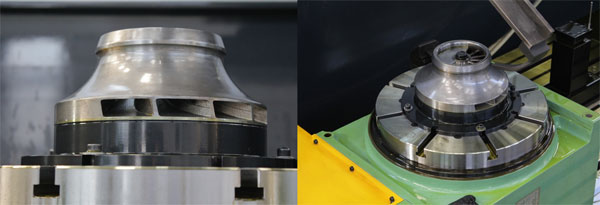

Machining of Twisted Cavity Parts of Centrifugal Compressor with Ternary Closed Structure

A number of electrodes used: 128 combined electrodes, 12 through large twisted channels.

Aero-engine intake titanium alloy grille

Number of electrodes used: 1 combined electrode, 60° whole plate oblique square hole processing, each processing 1 zone, each zone has square holes 668

Processing time: about 4.16 hours.

Rocket hydrogen-oxygen engine fuel injection collision hole

A number of electrodes used: 3 electrodes, processing quantity 1.

The hydrogen-oxygen fuel is required to accurately meet at a distance of 1m from the collision hole

Processing time: about 1.75 hours

Notes for maintenance of EDM small hole drilling machine

Notes for maintenance of EDM small hole drilling machine

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”