+86-13914052243

Windows Platform CNC EDM Machine

Windows Platform CNC EDM Machine

OVSO Series High Precision CNC Die Sinking EDM

OVSO Series High Precision CNC Die Sinking EDM

CNC EDM Sinker Machine C Structure A30, A45

CNC EDM Sinker Machine C Structure A30, A45

Ram Type CNC EDM Machine with Fixed Table

Ram Type CNC EDM Machine with Fixed Table

Double Heads Large CNC EDM Machine

Double Heads Large CNC EDM Machine

General Purpose CNC EDM Machine P40

General Purpose CNC EDM Machine P40

ZNC Die Sinking EDM Machine

ZNC Die Sinking EDM Machine

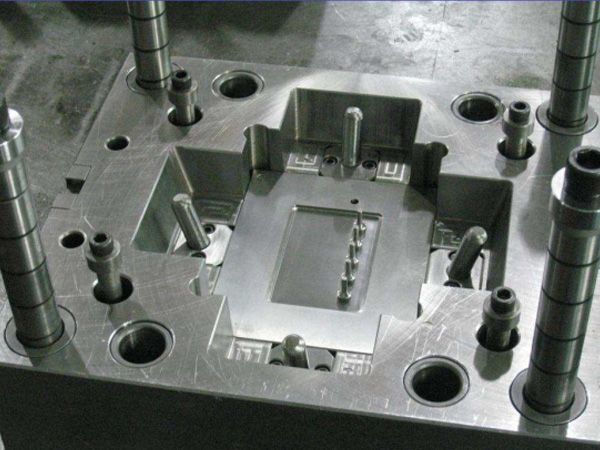

The machine body was designed and analyzed by advanced finite element analysis to make sure strong rigidity and long-term accuracy keeping.

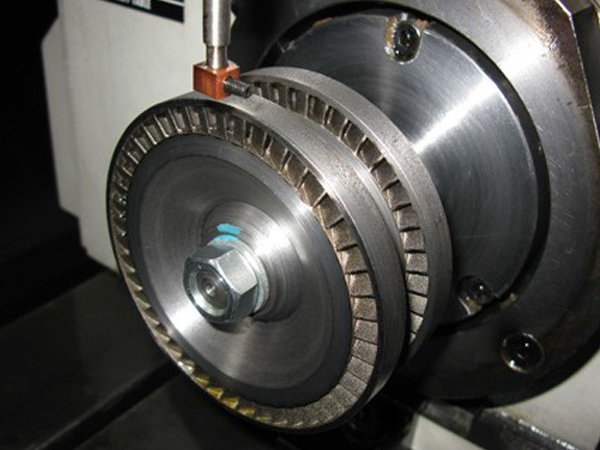

ADI300 and ADI450 utilize “T” shape machine bed, lower and wider bed, X and Y axis always moves in the range of machine body, to reduce deformation of machine body to keep sustainable geometric accuracy. “+” shape working table structure reduces the fluctuation error and deflection error of XY axis movement, to realize motion of control axis is smooth.

Adopt high quality casting with sufficient reinforcing ribs to reduce heat deformation of bed and column to realize stability of high-speed machining.

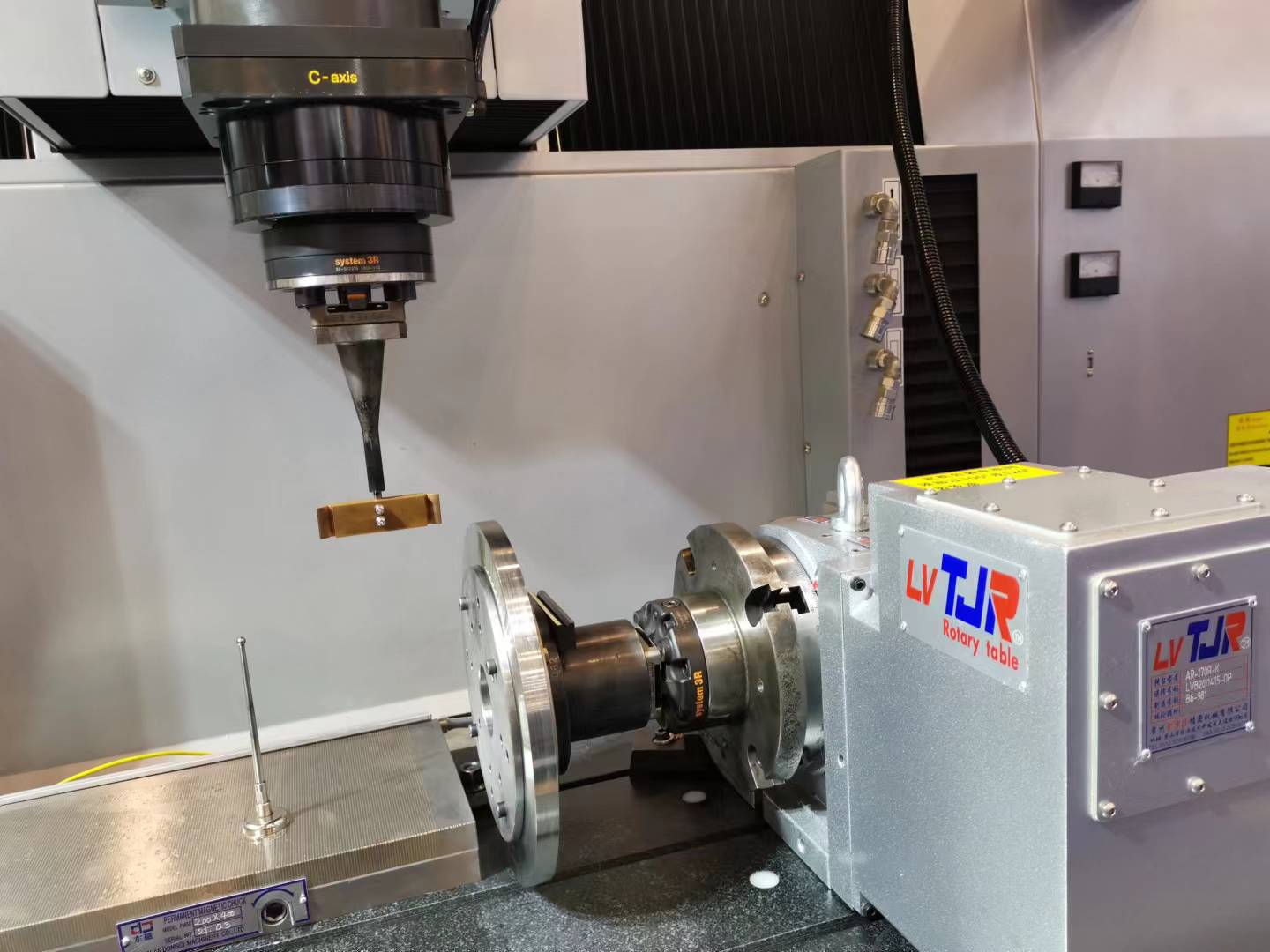

Single travel of Z axis with high rigidity design, the counterweight of spindle reduces the lag problem of spindle, to make sure high speed and high precision jump to increase machining speed.

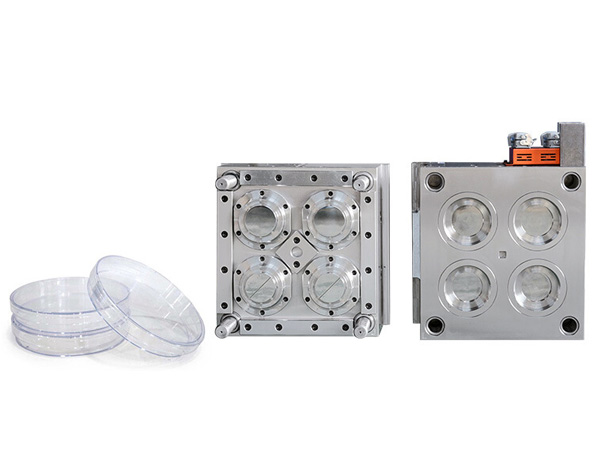

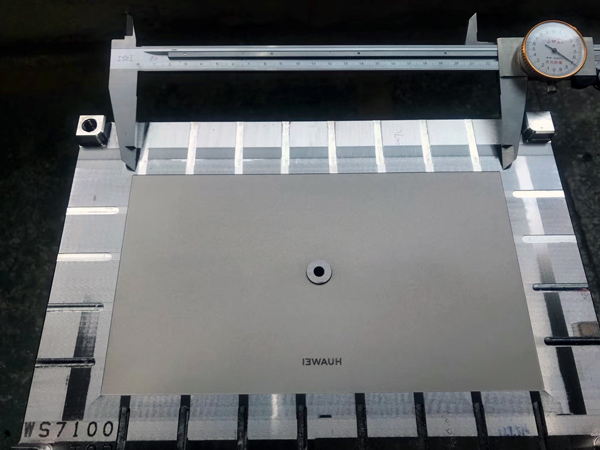

Adopt high quality marble working table, which has outstanding performance of isolation(efficiently keep sparking stability, which is very basic for spark erosion), less influence of temperature, anti-rust, anti-wear and etc. At the same time, it decreases the stray capacitance existing between two polarities during sparking, to increase evenness of mirror finish.

Latest 6th generation Windows platform advanced control system with expert machining assistance to make operating more convenient and efficient. The development of control system continues, update to the latest is always available.

Machining speed about 30% faster than 5th generation control system.

Standard with 3-axis control, up to 6-axis control.

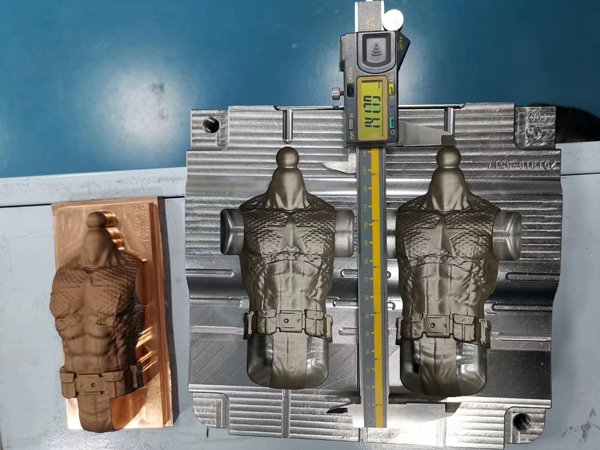

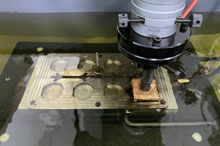

Own developed unique patents for the processing of difficult-to-machine materials to have realize the efficiency and high-precision machining of super-hard, high-temperature resistant materials (titanium alloys and super high temperature alloys).

Through the research of the early mirror finish circuit 1 and the research of the new discharging theory, DMNC independently developed the mirror finish circuit 2 machining circuits, so that the mirror surface finish effect increased from 25mm diameter to 50mm diameter.