+86-13914052243

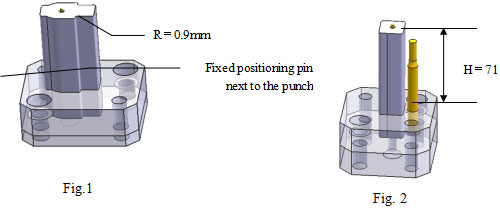

1) The male die has an R angle that is too small (less than 2 mm), and the CNC milling process can't process to the position, as shown in Figure 1.

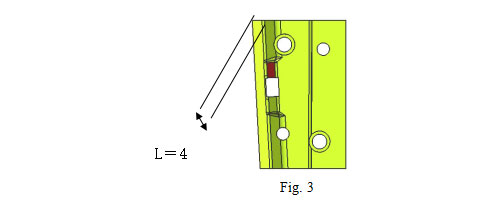

1) The male die punch is too long, and there is a fixed positioning pin beside it, the boring tool can’t process, and it can’t guarantee that the self-made punch and the standard fixed round can be processed by one cut, as shown in Figure 2.

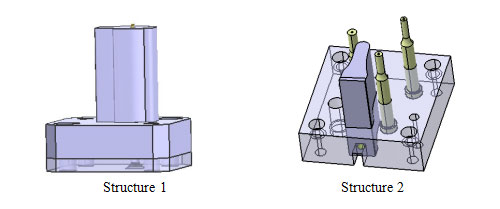

2) The punching die hole is close to the trimming line. If it is an SKD11 or Cr12MoV insert, the insert will be cracked after the cutter edge is milled and quenched. At this time, an EDM wire cutting machine is required, and the knife edge is cut after quenching. As shown in Figure 3.

1) In fact, if the R angle of the female die is too small (less than 2mm), and it is better to use wire cutting EDM too, otherwise the fitter will have to repair the female die according to the male die.

2) After quenching, it will be deformed, but if the accuracy is relatively high, it should be processed by a CNC EDM wire cut machine after quenching.

1) The first structure is to fix the punch with countersunk screws from the bottom of the backing plate.

2) The second structure is to punch a pin to prevent falling off from the side of the fixed plate.

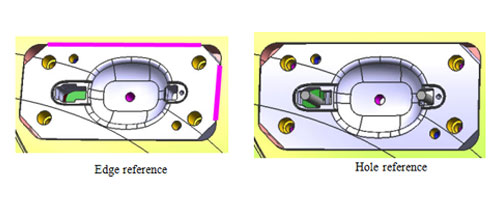

1) Edge reference: When inserting the insert into the mold base, while finishing milling the profile, do milling two 90° reference edges along the upper edge of the insert (record the data), milling down 10mm is enough, the two edges are best to match the mold X, Y-axis is parallel. Remove the insert for quenching, and then perform wire cutting EDM machining.

2) milling the profile, boring two reference pinholes at the appropriate position of the insert (recording data). The line of the center of the two pinholes is best to be parallel to the X or Y-axis. If you want to look more beautiful, the pinhole can be made inside the cut contour and used as a threaded hole at the same time, so that the pinhole will be gone after the EDM wire cutting. However, when using the pinhole as a threaded hole, the fit between the pin and the pinhole should not be too tight, otherwise, it is easy to shake the workpiece when the pin is pulled out.

3) It is not used as a reference base when do males die with wire cutting EDM machine, just cut out the shape. The position of the punch is positioned by the pinhole on the fixed plate. That is to say, the fixed round pin of the punch on the fixed plate and the pinhole is cut by one cut, and the corresponding positioning pinhole on the mold base is finely bored. In this way, in theory, there is no need for a fitter to match the punch gap, and it can be done in one step.

Principle: After finishing milling of the profile surface, CNC wire cutting after quenching, otherwise it will be deformed. Alloy steel is quenched as a whole unit, with large deformation, it must be quenched and then cut; air-cooled steel is surface quenched, although the deformation is small, it is still better to cut with CNC wire EDM after quenching.

1) Product tolerance: a tolerance range allowed by product design, for example, Φ8mm, that is, the product size is guaranteed to be qualified between Φ8.2 and Φ8.4.

2) Manufacturing tolerance: an allowable error range during processing, the manufacturing tolerance of the mold industry is 0.02mm.

3) Punching gap: the gap between the die and the punch when punching. Large gaps will have burrs, and small gaps will produce bright bands.

4) Principle:

The size of the punching hole is determined by the size of the punch, and the wear of the punch reduces the size of the punching hole;

The size of the blanking material is determined by the size of the die, and the wear of the die increases the size of the blanking material.

1) How to reasonably mark the size of EDM wire cutting:

In order to process products that meet tolerances when the punch or die is worn to a certain extent, it is necessary to fully consider the material thickness, size, accuracy, clearance, wear rules, processing characteristics, etc., and mark the reasonable cutting edge size and manufacturing tolerance.

Notes for maintenance of EDM small hole drilling machine

Notes for maintenance of EDM small hole drilling machine

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”