+86-13914052243

Full lines of CNC die-sinking EDM spark erosion machines are available to satisfy your needs, from sinking EDM machining automation production line to CNC EDM with automatic electrode changer to realize semi-automatic production; from ZNC EDM machine to 3 axes, 4 axes, 5 axis control EDM sinker; from small size to big size with double heads; from spark erosion machine with regular accuracy purpose to high accuracy machining. All you need for CNC EDM spark erosion machine for sale, this is the right place. DMNC has wire erosion machines for sale; Feel free to contact us to get our EDM spark erosion machine price!

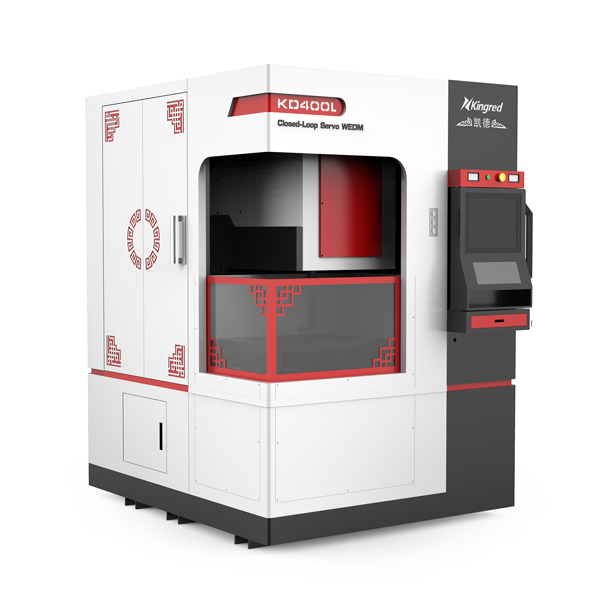

As one of the EDM machine suppliers, we are producing and supplying various molybdenum wire cut CNC EDM machines for sale, they are high-rank types of fixed column and moving column with fully covered sheet metal design, "C" structure and "T" machines bed with integrated design wire cutting machines, and economical conventional "F" structure wire EDM machines.

Range of EDM drilling machine(super drill) available: ZNC small hole EDM(X and Y manual) and CNC small hole drilling EDM with 3-axis, 4-axis, 5-axis, 6-axis, and up to 7 axis control, the diameter of electrode range from Φ0.08mm to Φ3.0mm, with option up Φ6.0mm, machine sizes from 400×300mm up to more than 1000mm travel. Feel free to contact us if you want any low price EDM drilling machine!

As we know there is dust while milling graphite material, special designed cutting liquid curtain of the high speed CNC milling machine keeps dust of graphite inside. Developed for machining graphite electrode for CNC die sinker, this type of machine is featured with High RPM spindle, high rigidity structure with FANUC controller to get the excellent performance of surface finish and accuracy, makes CNC graphite high-speed milling machine G-600, an automatic CNC milling machine, the ideal partner of producing high-quality electrodes used on types of EDM machines. It is worth mentioning that as the best Chinese CNC milling machine providers, you can 100% rest assures in DMNC.

Electrical Discharge Machining Computer Numerical Control, namely EDM CNC, is a special machining method that uses the electrical erosion effect produced by the pulse discharge between electrodes in the working liquid to remove the conductive materials. It is also called discharge machining or electrical erosion machining.

In EDM, the tool electrode and the workpiece are connected to the two poles of the pulse power supply respectively, and immersed in the working liquid, or the working liquid is charged into the discharge gap. The tool electrode is fed to the workpiece through the gap automatic control system. When the gap between the two electrodes reaches a certain distance, the pulse voltage applied on the two electrodes will break down the working fluid and produce spark discharge.

CNC EDM machine is mainly used for machining various kinds of molds, precision parts and other complex cavity and curved shape of various kinds of conductive materials.

CNC EDM machine can carry on the multi-coordinate linkage and process the complex shape parts. When machining parts change, generally CNC EDM machine only needs to change the numerical control program, which can save production preparation time. The machine tool equipment itself has high precision, high rigidity and high productivity.